AmbiLogique Ltd

Electronics, Instrumentation, Control, Automation

Prices?

Email us for a price list !

AMBILOGIQUE INDUSTRIAL CONTROL SYSTEMS

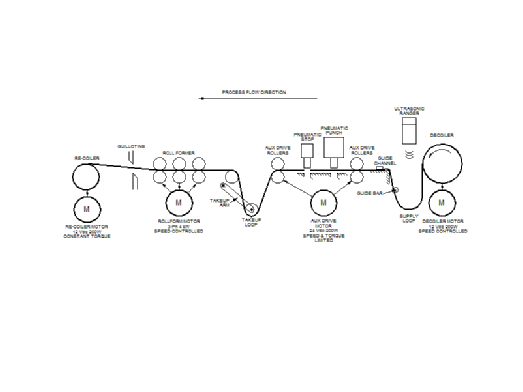

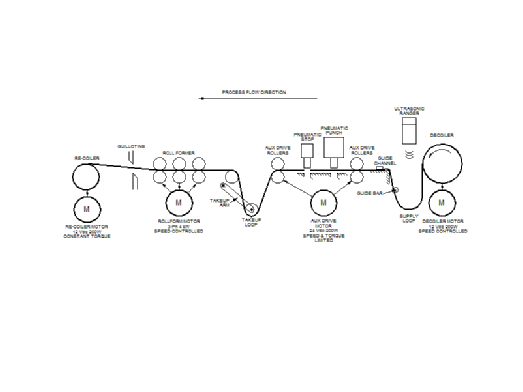

This is one of the more complex machines automated by AmbiLogique with a single PLC. The complete control system for this machine fits into one of the original CPDA-01 Processors (225 function blocks).

The machine takes stainless steel strip, punches it at exact intervals, rollforms it into a curved profile, and re-coils it into a form ready for retail packaging.

The strip starts as a large coil at left. This is fed out on demand, the supply loop being sensed by an ultrasonic ranger. The main feed through the machine is driven by a DC indexing drive. A pneumatic stop drops into the first hole punched in the strip; when it drops the indexing drive is switched off and the pneumatic punch creates the next hole. The sequence repeats.

A sprung takeup arm pulls the strip through the punch section; the position of the arm controls the speed of the 3-phase rollform motor. Finally the strip is rolled up on the re-coiler, and the machine stops after 100 metres of strip has been produced.

The two control panels are driven and sensed by an EXDA-01 built into the larger one and linked via a PLC backplane extension cable. In this way, 10 pushbutton controls and 9 indicators communicate with the PLC over a 4-wire screened cable.

Top left is the process schematic for the machine; top right is a general view; above is the punch and rollform section with the guillotine at far left.

Process flow is from right to left in all these views.

AmbiLogique has the capability to design, manufacture and commission complete automation systems. This punch-and-rollform machine is just one of many examples. It makes sealing strip for venetian-blind fire dampers in large-building air conditioning systems.